|

|

Proudly Designed and Built in the USA DYNAMEX is proud to celebrate 49 years of innovation, expertise & know-how, providing highly reliable equipment & unequalled support to the Wire & Cable Industry Auto-Splicing

Tape-Payoff

Models

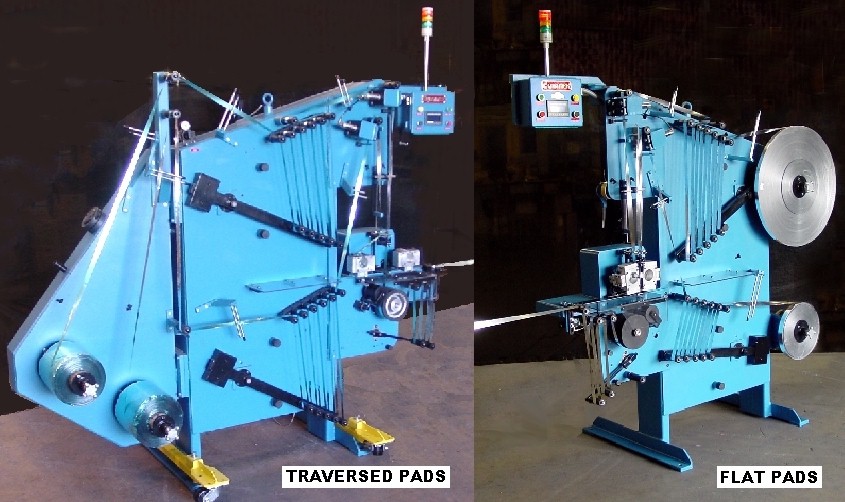

***************************************************

Models Are Available for Traversed

or Flat Pads, or Both Our

"Uni-Sex" Auto-Splicing Tape Payoff

Runs

Operation

at

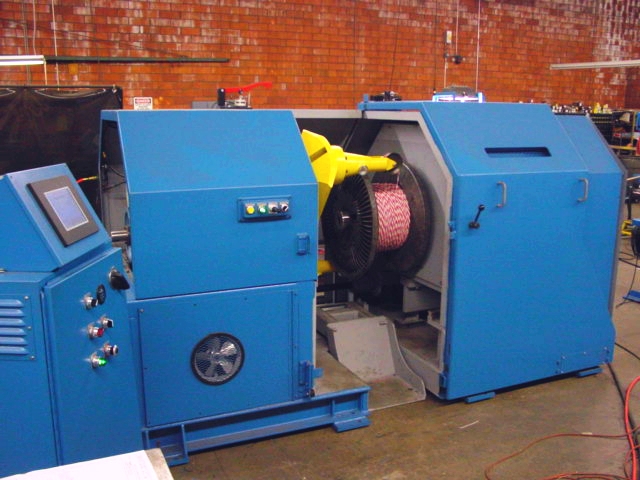

Line Speeds of OUR PRODUCT LINE: SINGLE TWIST

CABLERS & BUNCHERS

AUTO-SPLICING TAPE PAYOFFS up to 2,000 FPM AVAILABLE WITH LOW POSITION FOR

HEAVY PADS CLICK

FOR VIDEO OF RUNNING at 2000FPM

ALSO: SPOOLERS Non-Driven

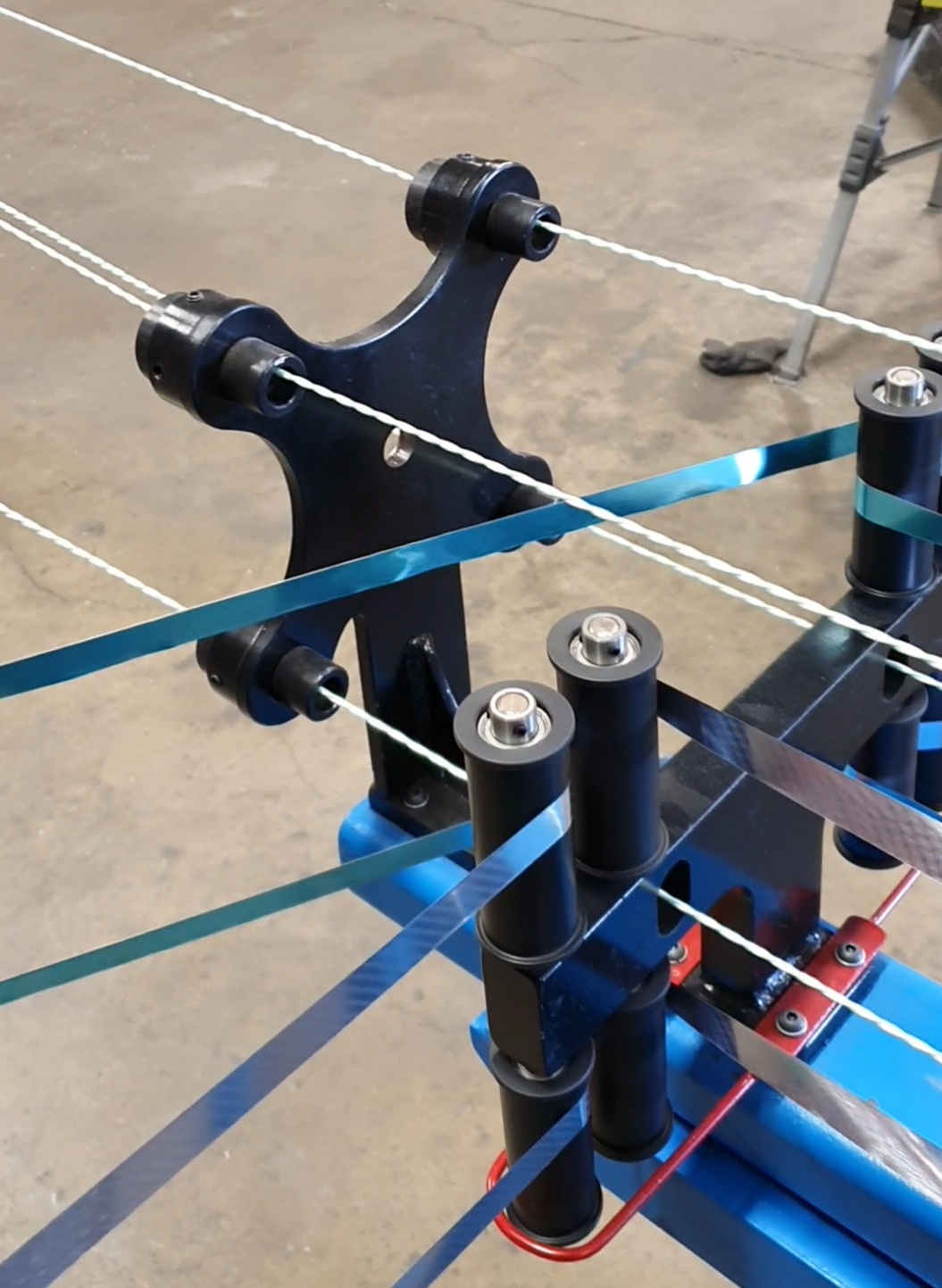

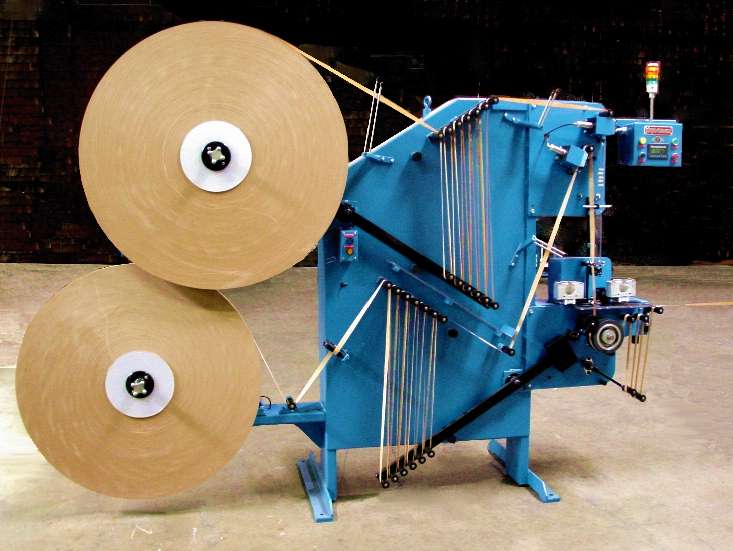

Dual Position Tape Payoff The tape travels to the Tape Roller Unit TRU3-2 or TRU3-2 which delivers the tape to the cable at the proper twisting angle and in a flat unwrinkled condition. The angle can be preset using the built-in scale and dial. A secondary adjustment helps prest a latteral displacement to provide optimal taping.

Tape

Payoff for In-Line Taping at Large Cablers Systems also available for 2" and 3" max tape width for taping while cabling -see below.

New Tape

Roller Guide Unit with DIAL-IN Angle

In order to better control

taping in-line with cabling Dynamex has recently

introduced a new roller unit (Model TRU2-2) that

eliminates the constant readjusting of roller

angles to keep the tape running

properly. This unit guides the tape up

to the point it begins wrapping on the cable, and

delivers the tape at the proper taping angle and

in a flat unwrinkled condition.. It enables

the operator to view the cable fully taped before

it enters the cabler. The tape-stand (which

Dynamex also offers) can be positioned anywhere,

and feed the tape from any direction, in front or

behind the wire line. The taping angle is

predetermined by the cable parameters and is

easily pre-set by the operator utilizing the

built-in scale and pointer. The angles are

marked in L/D values (lay to OD ratio) that are

easy for the operator or the foreman to

determine. The unit can be used for LH &

RH twist cables. It fits on the lead-in rail

that is supplied with Dynamex cablers. It

can also be made to fit on the mounting surfaces

available for other cablers. A die holder is

provided with the roller unit to assure consistent

smooth taping and prevent the cable from bowing

out due to tape tension. A non metallic

(home-made) die can be used in the die holder and

preferable the die can be of a split design, so it

can changed without cutting the cable. Two

units can be used in tandem for applications

requiring two tapes with or without drain.

Tape-Roller

Unit

with Pre-Dialed Tape Helix angle

************* High

Speed Auto-Splicing Tape-Payoff  for the European

and International markets runs & auto-splices Aluminized shielding tape, mylar, PE, Kraft paper, water block, etc (Click for Kraft paper Splicing Video)

(click to see animation)

DYNAMEX

CORPORATION Tel +1-310-329-0399 Fax +1-310-329-0159

|

|

|

||